We have a top market-share of this industry in Japan

We have created a good partnership with our customers by providing highly effective, functional products.

Features

- Each part is designed with installation in mind. It only needs a flat pit for installation, and it normally takes 1 day for installation to be completed.

- Although it depends on the environment where it is installed, our turntable maintains its capability for more than 10 years with periodic maintenance.

Standard product for parking lots

Custom made products are also available

| Type | Turntable diameter (mm) |

Movable load (kg) |

Standard Product Measurement in height (mm) |

Rotation speed (r.p.m) |

Motor (kw) |

Power source |

| ISB-40 | 4000 | 2500 | 450 | 1 | 0.75 | 3P/AC200V |

| ISB-45 | 4500 | 2500 | 500 | 1 | 0.75 | |

| ISB-55 | 5500 | 8500 | 600 | 1 | 1.5 × 2 |

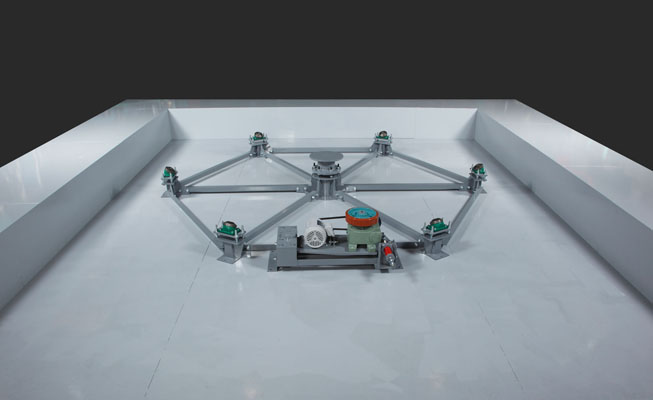

Instructions for installation

Click images for larger sizes

Principal mechanism

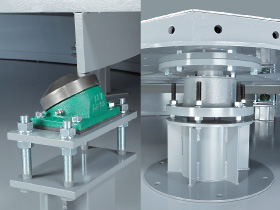

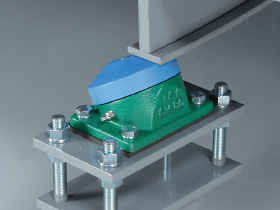

Base

Each base is independent. We can adjust the level by bolt parts.

Wheel and Axis

Wheels are our “Special Wheel” product and also Center axis is produced by us.

They hold up the top of the table and provide good rotation.

Drive Unit

It consists of 3 parts: roller, reduction gear, and motor.

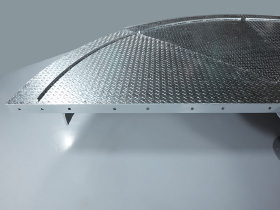

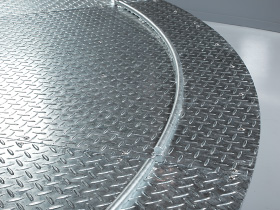

Top of Table

It is produced by us with our precious plate working technology.

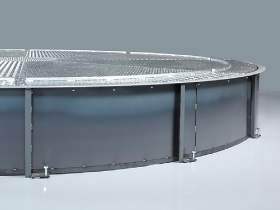

Corner Frame

It sets constant clearance between the turntable and surrounding surface.

Control Panel

There are 2 buttons, right and left, on the panel. Push the button to activate and release the button to stop. The turntable keeps rotating until you release the button. Installation type is independent type or wall-hanging type.

Options

Ring

It is helpful if it is impossible to keep usable dimension to rotate.

Zinc Plating

Zinc-treated checkered steel plate and corner frame is available. It is a cost effective method to prevent rust.

Zinc Treatment

All parts can be zinc treated to prevent salt damage or other forms of corrosion.

Low-noise capability

We can use MC Nylon in the head of SW Type Special Wheel to reduce noise.

Remote Control

Pay attention to safety in the surrounding area when it is used.

Installation process

As explained above, setting corner frame is the final process. But in certain instances, it is possible to be set before the table is installed.

Inverter

It enables slow-start rotation thereby the noise that occurs at first motion is reduced.