Ball Transfer Overview

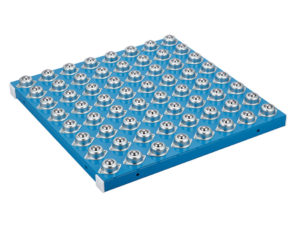

ISB Iguchi Kiko USA ball transfer units consist of a large load-ball that sits upon small balls encapsulated in a hemispherical cup. Our ball transfers fall into two categories, Ball-up type and Ball-down type castor like, also in some applications they are used to support from the side as a guide.

Their design creates a multi-directional, material-handling system that enables heavy loads to be moved smoothly along with minimal effort and friction. They are designed to assist in transferring, directing, or facilitating loading of flat products in workplaces such as warehouses, production lines, port cargo handling facilities, semiconductor production systems, FPD production system, PV, Solar glass handling production lines, medical equipment, research laboratories, under-floor facilities of buildings and offices manufacturing or freight transfer.

Similar to a roller system, the balls are installed within the table or work surface and the product rolls over the balls and allows for turning, lifting, directing or transferring from one conveyor line to another. People with lifting or carrying restrictions resulting from back, neck, shoulder, heart, and various repetitive strain injuries may benefit from the use of ball transfer technology if lifting or handling flat products on a repetitive basis within the workplace.

-

UM-B/BJ Type (3)

-

IS/IS-S Type (14)

-

IS-N/IS-SNM/IS-SN Type (21)

-

IS-B/IS-BF/IS-BM/IS-BK/IS-BD Type (17)

-

S Type (10)

-

IA/IA-R Type (6)

-

IM/IM-R/IM-J/IM-S/IM-SJ Type (10)

-

US/US-J/US-S/US-SJ Type (8)

-

IB/IB-S Type (4)

-

IJH/IJP Type (6)

-

IP Type (6)

-

IK Type (8)

-

IK-N/IK-SN/IK-SNM Type (15)

-

IBT Type (2)

-

UF Type (2)

-

IRT Type (3)

-

IRH Type (3)